Humane Field Harvest For High Quality Venison

Our process is unique in the world - the first fully inspected, year-round harvesting of truly free-range wild game meat. Wild animals humanely harvested provide ranchers income and customers with the purest meat available anywhere. Texas ranchers and biologists please visit our Harvest Benefits page for more information or to schedule a harvest.

Mobile Processing Facility

Wild deer and antelope become extremely stressed when trapped and transported. This stress negatively impacts the meat quality. We determined that instead of transporting the animals to a processing plant we would take the plant to the animals. In 1983 we built the first government approved mobile processing facility that would allow us to field-harvest animals and process them under full government inspection. Our harvest crew (shooter and skinner) and a government meat inspector travel to the ranch with one of our mobile processing facilities. The mobile processing facility is set up at a pre-arranged location on the ranch that minimizes the time lapse between harvesting and processing.

Humane Field-Harvesting

The ranch is quietly searched for deer and antelope. Animals are harvested in the field from long-range, typically 50 - 200 yards, using a sound-suppressed rifle and a high-power scope.

We have undertaken these unique field harvesting procedures in order to reduce stress during slaughter, which is a major factor in controlling meat quality. An animal that senses a threat or unusual situation will react with an increased flow of adrenaline which in turn creates a rapid increase in lactic acid within the muscles. This acidic condition causes the meat to become tough, strongly flavored, and reduces the shelf life of the meat. Farmed deer are slaughtered by loading them into a trailer, taking them to a slaughter house, and running them through an apparatus where they are killed and processed. Even though these deer are domesticated and relatively tame, there is certainly some stress introduced during this process. The purpose of our field harvesting technique is to ensure the animals are never under any stress and the resulting meat quality is the highest possible.

Field Processing Under Full Government Inspection

Once an animal has been harvested it is brought to our mobile processing facility where it is skinned, eviscerated, and inspected. Each animal is weighed and the rancher is paid for the total pounds harvested. Inspected carcasses are placed in the mobile processing facility's walk-in cooler to begin chilling, typically within one hour of harvesting. When the harvest is complete the meat is transported back to our Ingram facility where it is aged, packaged and shipped direct to customers nationwide.

|

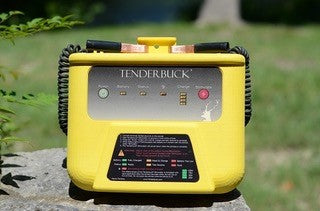

ELECTRO-STIMULATION: An additional step we take to ensure the quality of our meat is to electrostimulate all animals within minutes of harvesting. This process, developed for use by high-tech slaughterhouses, provides two important benefits which greatly enhance the quality of our products. The stimulation causes a contraction of muscles which ensures a thorough bleed out, guaranteeing a mild-tasting meat and longer shelf life. The electro-stimulation process also tenderizes the meat, producing meat which typically is 40% to 60% more tender than non-stimulated meat. We worked with Tenderbuck to develop portable electro-stimulation technology.

|